Call us now

08045478521- Home Page

- Company Profile

-

Our Products

- Straightening Machine

- SS Pipe Straightening Machine

- Pipe Straightening Machine

- Alloy Steel Bar Straightening Machine

- Steel Pipe Straightening Machine

- Coil Straightening Machine

- SRE Pipe Straightening Machine

- Metal Sheet Straightening Machine

- Steel Coil Straightening Machine

- Semi-Automatic Tube Straightening Machine

- Metal Coil Straightening Machine

- Auto Coil Straightening Machine

- Bar Straightening Machine

- Steel Section Straightening Machine

- Tube Straightening Machine

- Pipe Straightening Machines

- Tube Mill

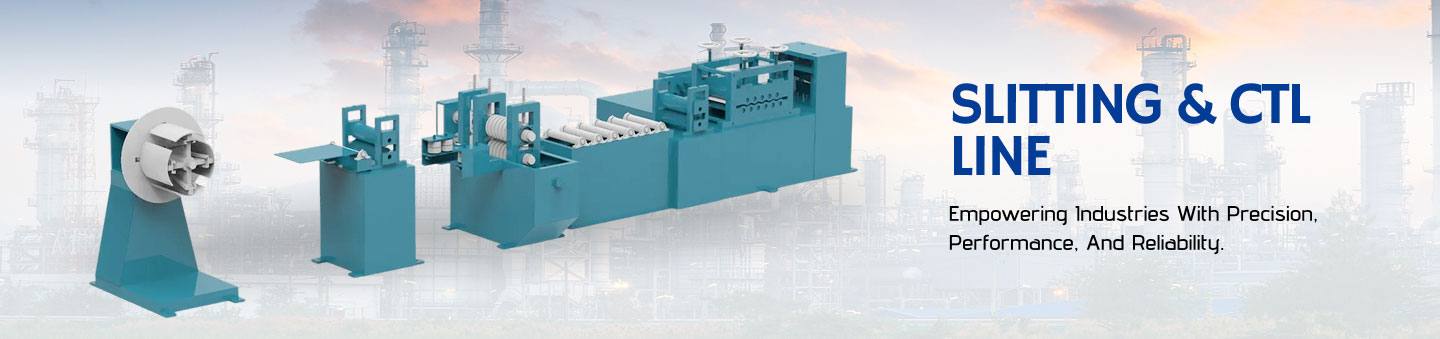

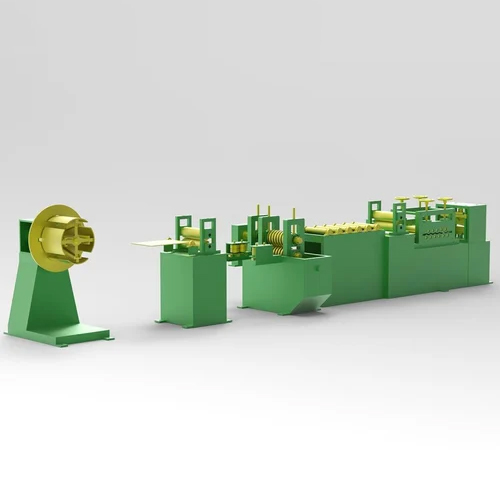

- CR And HR Slitting Line

- Draw Bench Machine

- Bar Peeling Machine

- Tube Polishing Machine

- Tube Pointing Machine

- Steel Pipe Making Machine

- Rolling Mill Machine

- Alloy Steel Bar

- Hydraulic Shearing Machine

- Bar Peeling Machines

- Slitting Machine

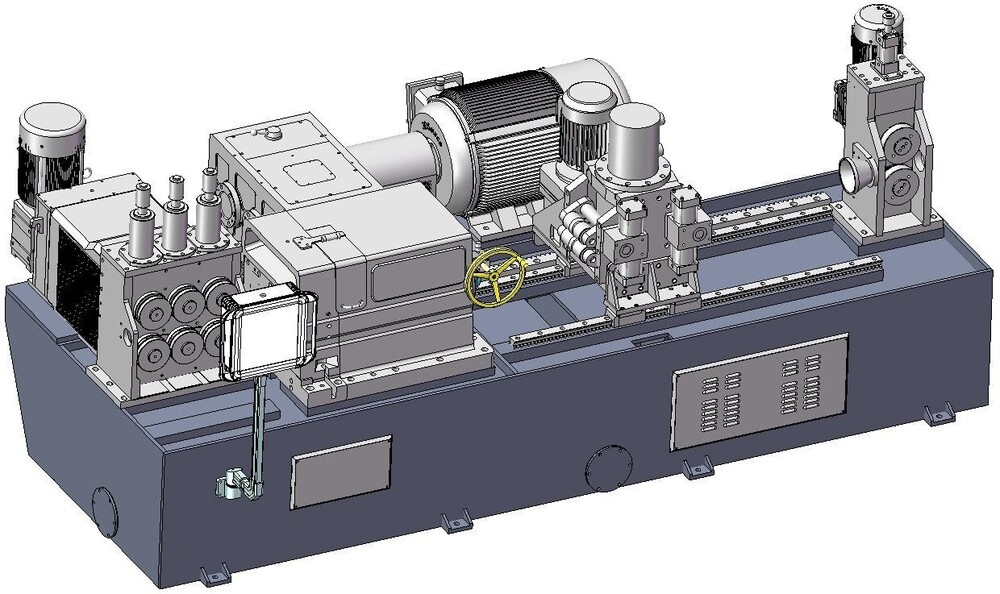

- Straightening Machine

- Contact